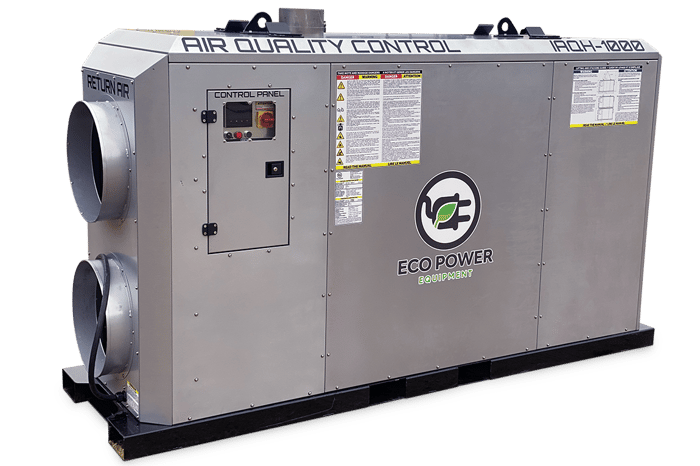

IAQH-1000

Eco Power Equipment

High-efficiency indirect heating for construction and temporary heat and humidity control applications.

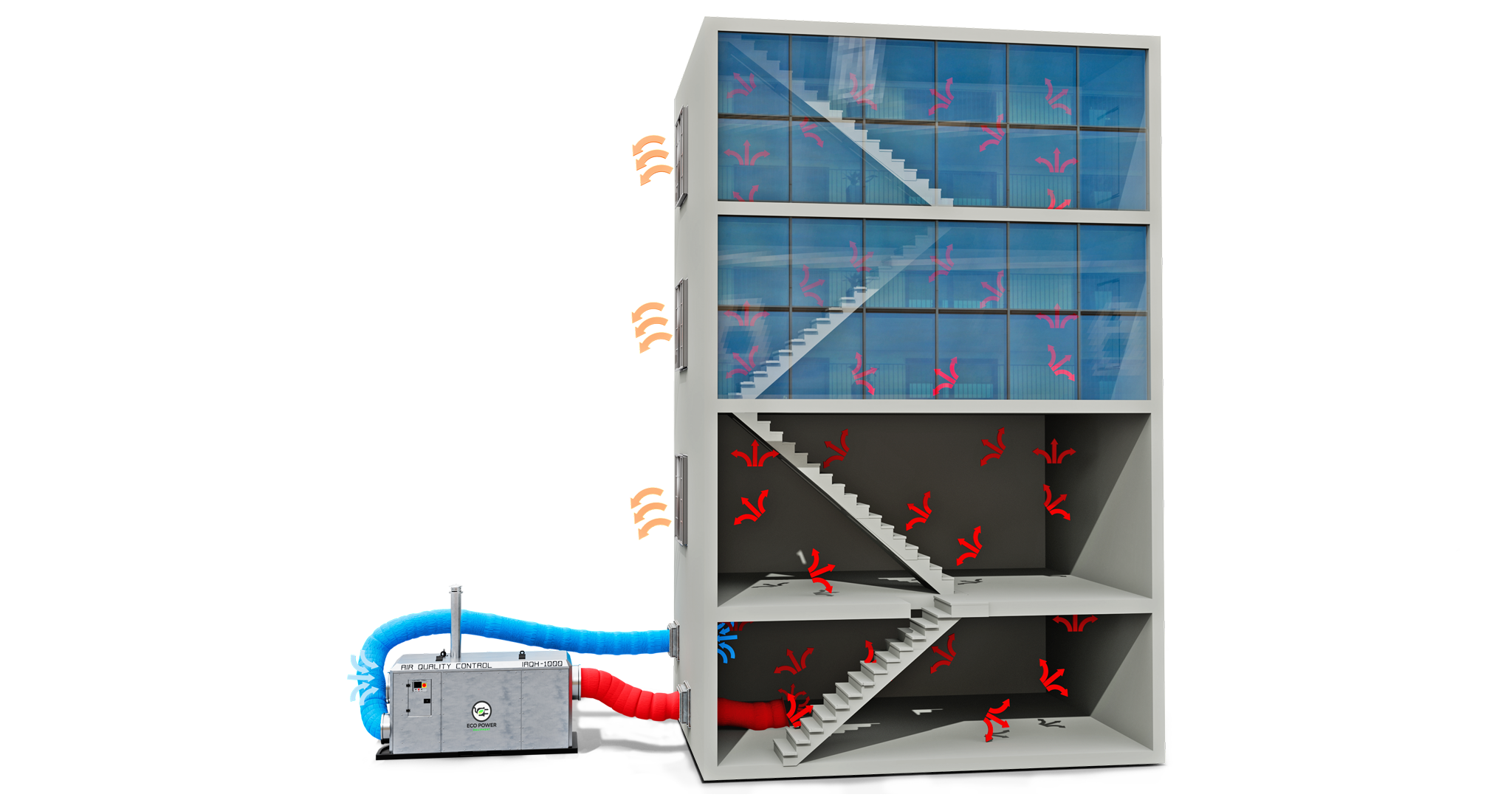

Controlling air quality during construction can dramatically increase project efficiency while delivering the highest quality finished product to building ownership.

- Reduced operating cost and emissions through fuel consumption savings

- Our heat exchangers include a primary drum and secondary exchange area made of 304L series stainless steel with great care in the design to reduce the cracking of welded joints.

- We focus on achieving results. Controlling the temperature and humidity to meet or exceed the specified parameters while operating at high efficiency reduces operating costs.

| Unit Specification | Details |

| Input BTU | 1,000,000 BTU/HR, 293 kW |

| Output BTU | 820,000 BTU/HR, 240 kW |

| Ducting Connection Size | 2 x 20" Inlet, 1 x 24" Outlet |

| Power Requirement | 208v Three Phase, 50/60HZ, 50 Amp |

| Product Certification | cETLus: CSA 2.14 / ANSI Z83.7 |

|

Gas Inlet Pressure |

10-14 inchs of water column, 25-35 millibar |

|

Gas Fuel Consumption |

NG 1.05 GJ / 27.8 M3 / 1000 ft3 per hour. LP: 41.3 Liters / 10.9 Gallons per hour |

| Air Volume Rating | 12,000 CFM |

| Heat Exchanger Type | Stainless Steel, 304L, 2 Pass Design |

We focus on providing solutions for temporary heating in the most efficient and practical manner.

The FACT is there are existing codes and guidelines for construction projects that provide recommendations for air quality environment during construction:

There are numerous advantages to using construction-grade temporary systems to control temperature, humidity, and air quality. A specific, tailored strategy needs to be established based on project details, and location.

- Our variable rate burner is ideal to provide forced mechanical ventilation for construction projects - supporting in site humidity level and moisture control, flushing and controlling air quality in-line with LEED credit 3.2

Design to meet modern air quality standards.

The requirements of modern construction and industrial processes and more stringent indoor air quality (IAQ) standards, have resulted in an increased demand for effective control of both industrial and commercial indoor spaces. For instance, ASHRAE Standard 62-1989 states, “Relative humidity in habitable spaces preferably should be maintained between 30% and 60%… to minimize the growth of allergenic and pathogenic organisms.” (Section 5.11).

Understanding the application is critical to achieving success - we place as much emphasis on engineering applications as we do on equipment. We give our application performance and operating efficiencies the utmost priority.

We have extensive market knowledge, having executed more than 250 projects to a high level of success. Please assist us in better understanding your project by contacting us for a no-obligation assessment and project recommendation.

Designed and field tested in one of the coldest weather conditions in North America.

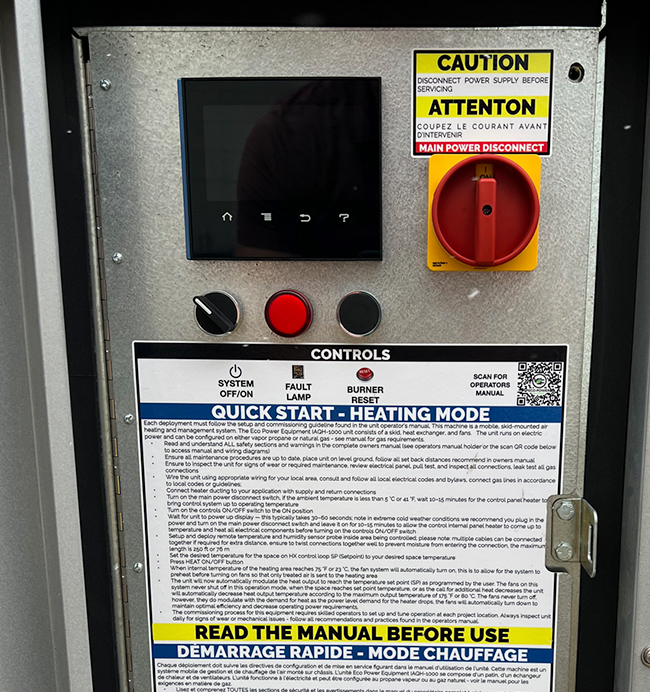

- We have field tested, and our products routinely are required to work in extreme ambient temperature conditions. All components are selected and designed to ensure the control system functions in even the most extreme cold conditions.

- Because of our modulating type design, you have the horsepower to produce high output heating while also being able to modulate down to match real-world situations. In addition, with reduced burner cycling and an unmatched uptime guarantee, we can operate in extreme cold and difficult power circumstances without experiencing any downtime.

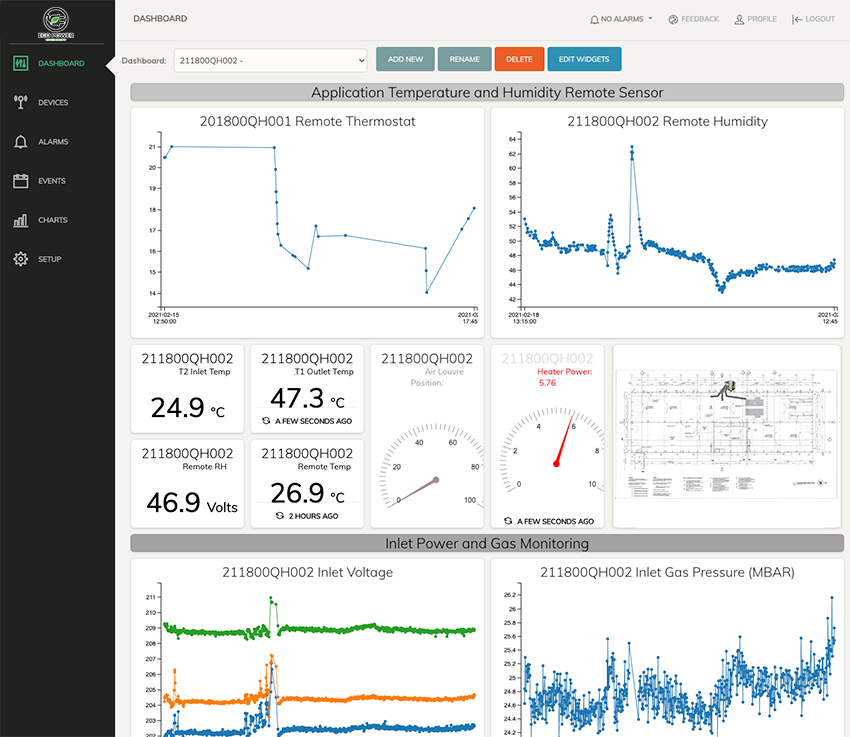

Ready out of the box for remote management.

It's not enough to provide excellent equipment; application performance monitoring and advanced two-way equipment communication are critical.

- The IAQ Cloud has been designed to empower Eco Power Dealers to provide end-user solutions at scale. Remote management and fault protection allow a new vision for managing equipment operations and performance.

- Manage and log temperature and humidity levels on-site during the construction phase

- Optimize the construction process for speed and quality

- Manage uptime for critical applications

- Fleet management

- Readout and monitor inlet gas pressure and power voltage on the digital readout, logging of both conditions during operation for advanced diagnostics and troubleshooting